| Model | Volume(m3) | Feeding quantity(kg/second) | Overall dimension (mm) | Mixing time(min) | Stirring speed(r/min) | Motor power(kw) | Discharge motor power(kw) |

| CF-CXM-50 | 0.05 | 38 | 1300*1000*540 | 6-15 min | 28 | 1.5 | 0.55 |

| CF-CXM-100 | 0.1 | 83 | 1400*1100*600 | 6-15 min | 26 | 2.2 | 0.55 |

| CF-CXM-150 | 0.15 | 124 | 1360*1120*600 | 6-15 min | 24 | 3 | 0.55 |

| CF-CXM-200 | 0.2 | 140 | 1460*1200*600 | 6-15 min | 24 | 4 | 0.55 |

| CF-CXM-300 | 0.3 | 210 | 1820*1240*680 | 6-15 min | 24 | 5.5 | 1.5 |

| CF-CXM-400 | 0.4 | 310 | 2000*1240*780 | 6-15 min | 20 | 5.5-6 | 1.5 |

| CF-CXM-500 | 0.5 | 350 | 2150*1240*780 | 6-15 min | 18 | 6-7.5 | 2.2 |

| CF-CXM-750 | 0.75 | 560 | 2200*1240*780 | 6-15 min | 16 | 7.5-6 | 2.2 |

| CF-CXM-1000 | 1 | 780 | 2300*1260*800 | 6-15 min | 16 | 11-6 | 3 |

| CF-CXM-1500 | 1.5 | 1150 | 2500*1300*860 | 6-15 min | 12 | 11-6 | 3 |

| CF-CXM-2000 | 2 | 1500 | 2600*1400*940 | 6-15 min | 12 | 6-15 | 4 |

| CF-CXM-2500 | 2.5 | 2100 | 3000*1560*1160 | 8-20min | 12 | 5-6 | 5.5 |

| CF-CXM-3000 | 3 | 2250 | 3800*1780*1500 | 8-20min | 10 | 6-12 | 7.5 |

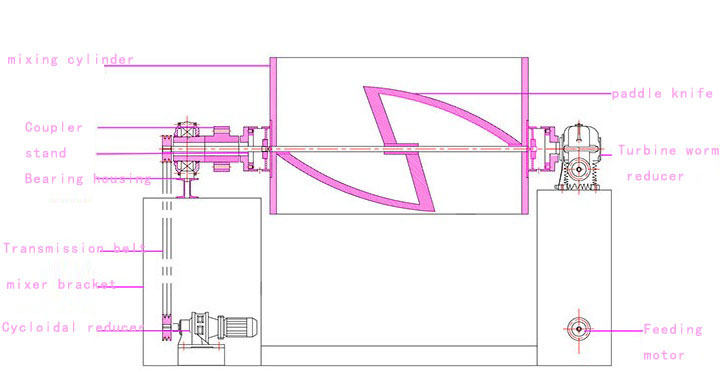

● Good dispersion: The equipment completely solves the problems of low uniformity and dead angle caused by the different proportions of materials. This equipment adopts a mixed structure of five-axis with flying knife mortar, which can effectively disperse various staple fibers. ● Wide range of use: The equipment can meet the production of dry mortar with different performance requirements. Such as: masonry mortar, plaster mortar, polymer mortar required for thermal insulation system, polystyrene particle moisturizing mortar and other dry powder mortar. ● Small investment: The device has obvious price advantages. Small investment, quick results. ●Simple and convenient to use: the equipment has a small footprint, simple operation, low energy consumption, and can produce 5-8 tons per hour. ●Long service life: The vulnerable parts of this equipment are all made of high-strength wear-resistant steel as parts. It has the characteristics of long service life.

● Good dispersion: The equipment completely solves the problems of low uniformity and dead angle caused by the different proportions of materials. This equipment adopts a mixed structure of five-axis with flying knife mortar, which can effectively disperse various staple fibers. ● Wide range of use: The equipment can meet the production of dry mortar with different performance requirements. Such as: masonry mortar, plaster mortar, polymer mortar required for thermal insulation system, polystyrene particle moisturizing mortar and other dry powder mortar. ● Small investment: The device has obvious price advantages. Small investment, quick results. ●Simple and convenient to use: the equipment has a small footprint, simple operation, low energy consumption, and can produce 5-8 tons per hour. ●Long service life: The vulnerable parts of this equipment are all made of high-strength wear-resistant steel as parts. It has the characteristics of long service life. 1. Regularly check the machine parts, 1-2 times a month, check whether the worm gear, worm, bearing, shaft seal and other active parts are flexible and wear, and the defects should be repaired in time so that the groove mixing function can be used normally; 2. The electrical control parts of the slot mixer should be kept clean and sensitive, and the fault should be repaired in time; 3, the lubrication of the parts: the lubrication of the reducer adopts oil immersion type, and its oil storage amount must be kept on the oil marking line, and the oil quality must be kept clean. If you use it regularly, you must change the new oil every three months, and when replacing, you should disassemble and clean the reducer, and add new oil; 4. When the use is completed or the work is stopped, the remaining materials in the mixing tank should be taken out and the residual powder of each part of the machine should be brushed. If the deactivation time is long, the groove mixer must be wiped clean and covered with an unkempt cloth.1. The volume can be customized, the mixing effect is good, and the uniform mixing degree of the material can reach more than 99.5%. 2. The mixing method can be configured with different mixing rod shapes according to different materials, such as single and double screw belt or screw belt + throwing knife 3. The stirring effect of low energy consumption is more suitable for the chemical reaction of the material 4. A variety of closed feeding methods are preferred for feeding, and the caliber can be seamlessly closed 5. The discharge method is reasonable and efficient, so as to achieve no residue of the material, and the discharge is more thorough and stable 6. Realize the efficient mixing of powder-liquid mixing, powder-powder mixing and powder-solid powder, which is especially suitable for material mixing with high mixing uniformity requirements and large material specific gravity difference.

1. Regularly check the machine parts, 1-2 times a month, check whether the worm gear, worm, bearing, shaft seal and other active parts are flexible and wear, and the defects should be repaired in time so that the groove mixing function can be used normally; 2. The electrical control parts of the slot mixer should be kept clean and sensitive, and the fault should be repaired in time; 3, the lubrication of the parts: the lubrication of the reducer adopts oil immersion type, and its oil storage amount must be kept on the oil marking line, and the oil quality must be kept clean. If you use it regularly, you must change the new oil every three months, and when replacing, you should disassemble and clean the reducer, and add new oil; 4. When the use is completed or the work is stopped, the remaining materials in the mixing tank should be taken out and the residual powder of each part of the machine should be brushed. If the deactivation time is long, the groove mixer must be wiped clean and covered with an unkempt cloth.1. The volume can be customized, the mixing effect is good, and the uniform mixing degree of the material can reach more than 99.5%. 2. The mixing method can be configured with different mixing rod shapes according to different materials, such as single and double screw belt or screw belt + throwing knife 3. The stirring effect of low energy consumption is more suitable for the chemical reaction of the material 4. A variety of closed feeding methods are preferred for feeding, and the caliber can be seamlessly closed 5. The discharge method is reasonable and efficient, so as to achieve no residue of the material, and the discharge is more thorough and stable 6. Realize the efficient mixing of powder-liquid mixing, powder-powder mixing and powder-solid powder, which is especially suitable for material mixing with high mixing uniformity requirements and large material specific gravity difference.